- Browse Categories

- Mechanical measurement device

- PJK Brand Monitoring System

- Optical Survey Instruments

- RTK GNSS Systems

- Pipeline Detector/ Locator & GPR

- Unmanned Aerial Vehicle Payload

- Thermal Camera

- 3D Laser Scanner

- Wet Blast Machine

- Measuring instrument Plainmeter

- Weather Station Series

- SDI Soil Tester

- UAV/ Unmanned Aerial Vehicle

- Module

- Viscometer

- Electric Hygro-thermograph

- Spectrometer

- Echo Sounder

- Processing Software

- Keson Measuring Tools

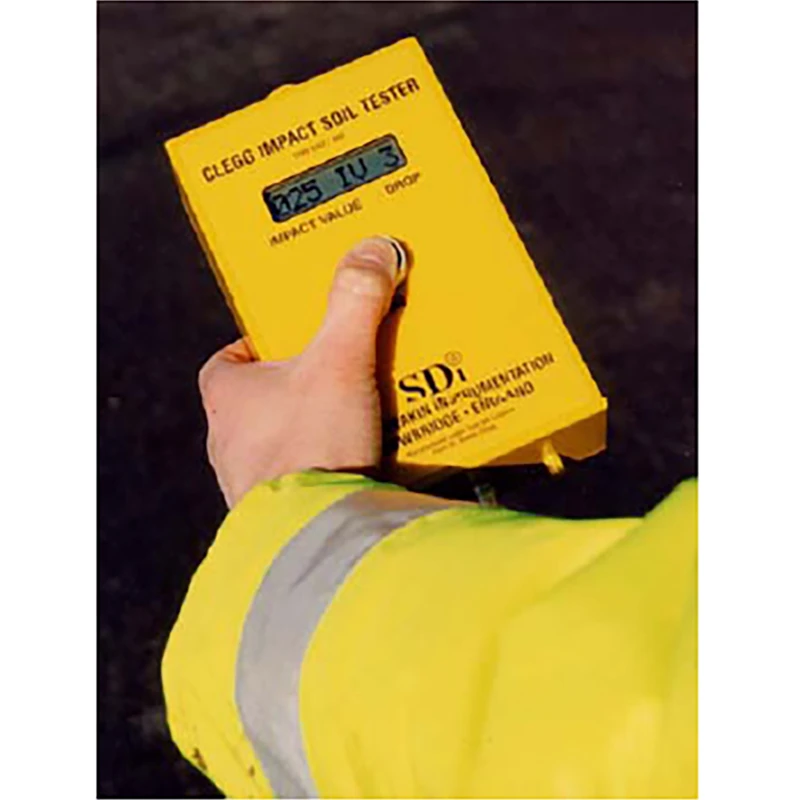

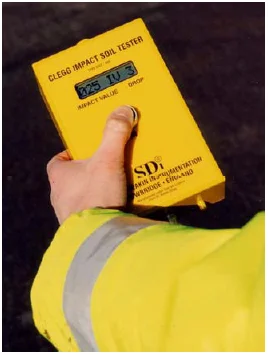

CLEGG IMPACT SOIL TESTER Type CIST/882

The Clegg Impact Soil Tester type CIST/882 manufactured by SD Instrumentation (SDi) provides a means for measuring and controlling soil strength and consolidation levels during trench re-instatement. It is also used to confirm uniform compaction over wide areas of ground, identifying poorly compacted areas and ineffective rolling of materials. A special lightweight version of the Tester is also available for checking sports turfs whilst a heavy duty version is supplied for testing harder materials and roadworks.

The Tester consists of a 4.5 kg compaction hammer operating within a vertical guide tube. When the hammer is released from a fixed height, it falls through the tube and strikes the surface under test, decelerating at a rate determined by the stiffness of the material within the region of impact. A precision accelerometer mounted on the hammer generates an electrical charge which is fed by a cable to a hand-held digital readout unit. The readout unit scans and filters the signal and registers the deceleration in units of Impact Value (IV). The Impact Value is an indication of soil strength and shows good correlation with results from CBR tests. Data from the Impact Soil Tester can therefore be used in a similar manner to results from CBR tests performed in the laboratory and in the field.

CIST/882 HAND-HELD READOUT UNIT

The CIST/882 Readout Unit is held in the hand during testing. It displays readings of Impact Value (IV) and also shows the number of times that the hammer has been dropped during each test operation. Unlike previous models the user does not need to keep the ‘On’ button pressed during testing.

To carry out a test, the ground surface is brushed lightly with the foot to remove loose material and the guide tube is placed in position. With the digital readout switched on and held in one hand, the hammer is raised to a height of 450 mm as indicated on the hammer head and then allowed to fall freely. This procedure is repeated four times, the forth reading is taken as the Impact Value.

Tag:

Shenzhen Peng Jin Technology Co., Ltd.

Tel:+8613828792860

Wechat:PJK13828792860

Contact Person:Janet luo

PDF Show:PDF