- Browse Categories

- Mechanical measurement device

- PJK Brand Monitoring System

- Optical Survey Instruments

- RTK GNSS Systems

- Pipeline Detector/ Locator & GPR

- Unmanned Aerial Vehicle Payload

- Thermal Camera

- 3D Laser Scanner

- Wet Blast Machine

- Measuring instrument Plainmeter

- Weather Station Series

- SDI Soil Tester

- UAV/ Unmanned Aerial Vehicle

- Module

- Viscometer

- Electric Hygro-thermograph

- Spectrometer

- Echo Sounder

- Processing Software

- Keson Measuring Tools

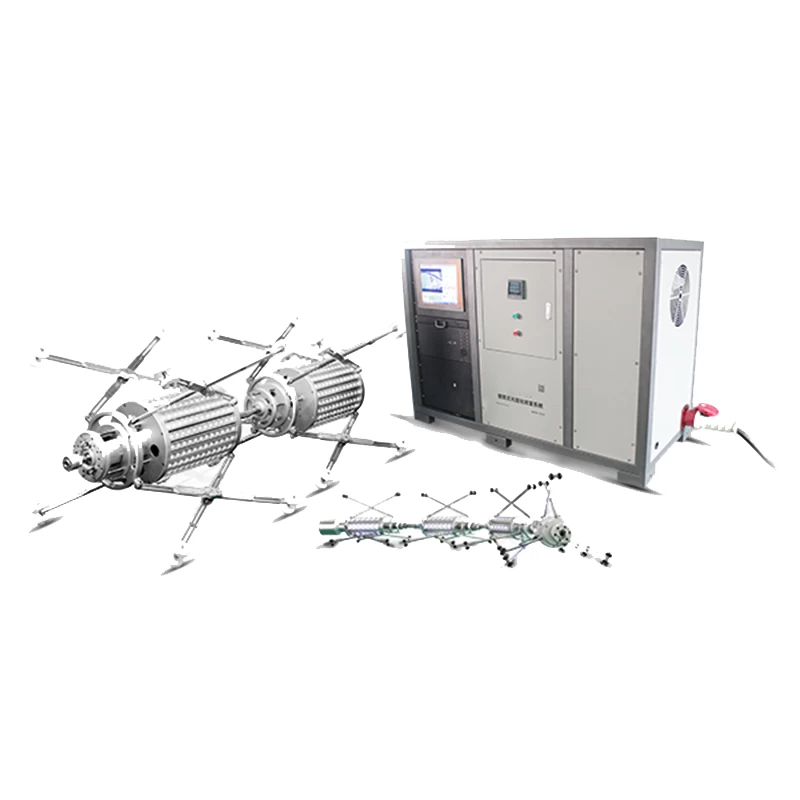

GO120-D Controllable Point Repair System

- Brand name: Geoinstru

- Model name: GO120-D

- Origin: China

- Warranty period: 1 year

- Support Express: Shipping, Airmail

GO120-D Controllable Point Repair System

The control point repair system mainly consists of two parts: the main control system and the airbag. Its main features are high efficiency, stability, accuracy and control, allowing damage sites to be repaired in 6 minutes.

Scope:

Urban (industrial) drainage pipes

Product overview

GO120-D Controllable Point Repair System is primarily used to repair defective points in drain points. Select the corresponding airbag according to the pipe diameter to accurately repair the damaged area.

The GO120-D Controllable Point Repair System consists primarily of two parts: the main control system and the airbag. Its main features are high efficiency, stability, accuracy and control, allowing damage sites to be repaired in 6 minutes.

Product Features

1. High efficiency: The repair time is 5-8 minutes, 1/5 of the natural hardening point repair method.

2.Stability: Don't be afraid of cold or heat, and are not affected by the environment.

3. Accuracy: Airbags can be accurately placed on the parts to be repaired through video and encoder.

4. Controllable: Equipped with a 5.5-inch Sunshine Visual OLED screen, the curing process is controllable and the entire restoration process can be video surveillance in real time.

Technical specifications

1. Main control functions: automatic wiring, wiring speed adjustment, airbag charging and discharging, UV lamp switch;

2. Cable length: Standard cable length is 80 meters, and cable meter mark is every 1 meters.

3. Auto-wiring: Ensure regular wiring of cables on the winch disk during the process of receiving and ejecting wiring.

4. Count: Using a high-precision encoder, the count resolution is 1mm.

5. Power supply: AC220V input, maximum instantaneous power of 3KW, recommended 5KW generator power source;

6. The specifications and parameters for the three standard airbags are as follows:

|

Airbag specifications |

CA1 |

CA2 |

CA3 |

|

Minimum repair pipe diameter (mm) |

200 |

300 |

400 |

|

Maximum repair pipe diameter (mm) |

300 |

450 |

600 |

If you are interested in this product, please feel free to contact us.

Tel:+8615899753550

Wechat:pjk2018666

Contact Person:Linda Lin

PDF Show:PDF