- Browse Categories

- Mechanical measurement device

- PJK Brand Monitoring System

- Optical Survey Instruments

- RTK GNSS Systems

- Pipeline Detector/ Locator & GPR

- Unmanned Aerial Vehicle Payload

- Thermal Camera

- 3D Laser Scanner

- Wet Blast Machine

- Measuring instrument Plainmeter

- Weather Station Series

- SDI Soil Tester

- UAV/ Unmanned Aerial Vehicle

- Module

- Viscometer

- Electric Hygro-thermograph

- Spectrometer

- Echo Sounder

- Processing Software

- Keson Measuring Tools

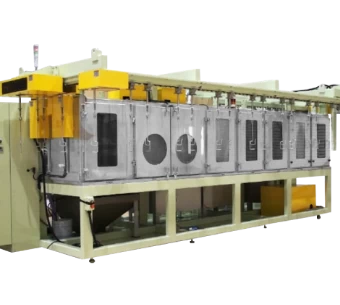

BL-740-TH Barrel type wet-blasting and conversion coating equipment

- Brand Name:Macoho

- Model Name:BL-740-TH

- Place of Origin:Japan

- Warranty:1 year

- Support Express:Sea freight, air freight

BL-740-TH

Barrel type wet-blasting and conversion coating equipment

Wholesales wet abrasive blasting equipment A system than can automatic processing of cleaning, surface roughening and conversion coating

Tumble barrel type wet-blasting and Phosphate conversion coating equipment which has a large capacity to process, as it has a drum type barrel for continuous automatic processing of degreasing, cleaning, roughening and conversion coating to metal fittings. It is applicable for complex shaped work pieces such as a cylindrical shaped bush and mount etc. or sheet shaped work piece like metal fitting for disc brakes.

Feature

- A tumble-barrel at the blasting part is used and therefore a whole treatment of metal fittings with effective stirring is applicable.

- A whole process work piece on various shapes, such as complex, cylindrical and plank shapes are applicable.

- An unique barrel drive is applied for a metal fitting transferring method in the treatment liquid tank, and it can prevent deterioration of the liquid due to mixture.

- Processing with stable quality is applicable, since the work piece will surely be moved to the next tank at a constant speed.

Specification

| Size | 12327(W)×3850(D)×3895(H)mm (Equipment) |

|---|---|

| Work piece | Complex shaped metal fittings |

| Work size | Basic size : 150×150mm and below Basic weight : 1kg / piece and below |

| Capacity / batch | max. volume : max.40L max. weight : max.50kg |

| Processing time | 100s per batch (standard) |

| Gun | Φ11×8-multi Zigzag Gun |

| Power supply | AC200V, 50/60Hz, 3 phases |

| Power consumption | About 34kW (Total rated apparent power of all the equipment) |

| Air supply pressure | 0.5MPa-0.7MPa |

| Air consumption | 12.5m3/min (NTP at 0.4 MPa of preset blast air pressure) |

| Water supply | 1.3m3/h (Normal) |

| Steam pressure | 0.5MPa-0.7MPa |

| Steam consumption | 400kg/h (NTP at 0.4 MPa of preset blast air pressure) |

| Exhaust | Blast : 12m3/min ×2 Phosphate : 15m3/min Dry: 15m3/min Transfer : 12m3/min |

| Option | Feeder, Discharger, Abrasive automatic supply unit, Blast Sludge Recovery unit, Phosphate Sludge Recovery unit. |

Related products

|

|

Automatic equipment capable of full-surface processing of complex shaped parts hung on a hanger

|

|

|

|

|

Amazing base treatment (WBP) that firmly bonds metal parts and rubber

|

Tel:+8615899753550

Wechat:pjk2018666

Contact Person:Linda Lin

PDF Show:PDF